How to Choose the Right Core Drilling Rig for Your Project Needs: The Advantages of Portable and Lightweight Options

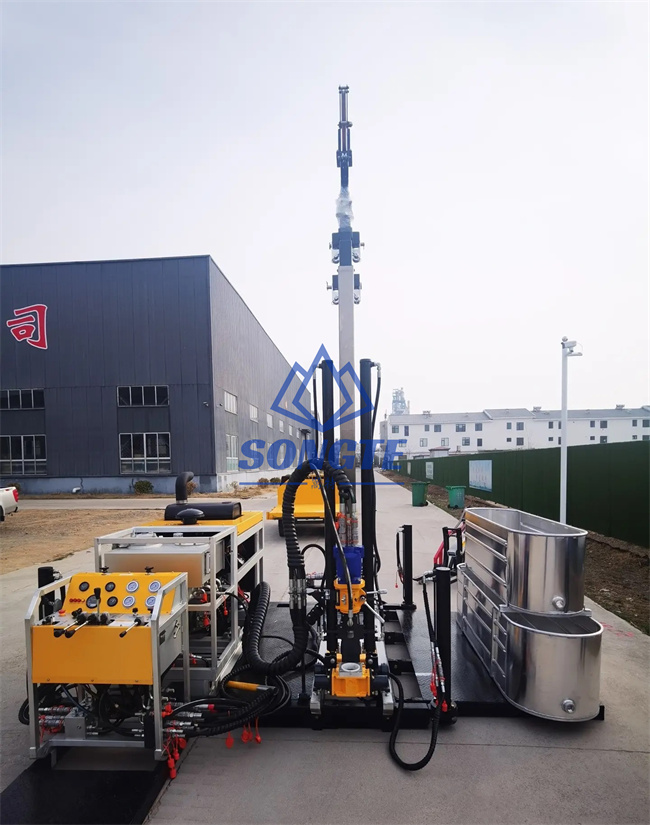

300m Hydrogeological Investigation Core Drilling Rig (SC-F300D)

Introduction

Selecting the appropriate core drilling rig is a crucial decision in any drilling project. The choice you make can significantly impact the efficiency, cost-effectiveness, and success of your endeavor. With a variety of core drilling rigs available, it’s essential to understand your project’s unique requirements and the advantages of different rig types. In this article, we will guide you through the process of choosing the right core drilling rig and explore the benefits of portable and lightweight options.

Understanding Your Project Requirements

Before delving into the advantages of portable and lightweight core drilling rigs, it’s important to assess your project’s specific needs. Consider the following factors:

Project Type: Determine the nature of your project. Are you conducting geotechnical investigations, mineral exploration, or construction work? Different projects may require specialized rigs.

Material Type: Identify the materials you’ll be drilling into—whether it’s rock, concrete, soil, or other substances. The hardness and composition of the material will influence your rig choice.

Drilling Depth: Evaluate the depth of drilling required. Some rigs are designed for shallow drilling, while others can reach greater depths.

Mobility: Decide whether your project demands a mobile or stationary drilling rig. Consider whether you’ll need to transport the rig to multiple locations or if it will remain in one place.

Power Source: Depending on your project site’s power sources, you may need an electric, hydraulic, or pneumatic drilling rig. Ensure compatibility with your power supply.

Budget: Set a budget for your drilling equipment. While cost is a factor, it’s also crucial to prioritize quality and durability to avoid unexpected downtime and maintenance costs.

Advantages of Portable and Lightweight Core Drilling Rigs

Portable and lightweight core drilling rigs offer several key advantages that make them a preferred choice for many projects:

Mobility: Portability is a standout feature of these rigs. They are designed to be compact and easy to transport, making them ideal for projects in remote or challenging locations. This mobility is especially valuable for geological surveys or exploration in rugged terrain.

Versatility: Portable rigs are versatile and adaptable to various applications. Whether you’re collecting soil samples, conducting concrete testing, or exploring for minerals, a lightweight rig can accommodate different project needs.

Quick Setup: Lightweight rigs are engineered for rapid deployment. Their straightforward setup reduces downtime, allowing you to begin drilling operations quickly, which can be critical for time-sensitive projects.

Reduced Environmental Impact: In environmentally sensitive areas or confined spaces, a smaller and lighter rig minimizes the impact on the surroundings. This is beneficial for projects that require drilling in tight quarters or near ecologically sensitive areas.

800m Core Drilling Rig For Mineral Exploration (SC-F800D)

Cost-Effectiveness: Portable and lightweight core drilling rigs are often more budget-friendly than larger, specialized rigs. They strike a balance between performance and affordability, making them a cost-effective choice for many applications.

Accessibility: These rigs can access spaces that may be challenging for larger equipment. This accessibility is valuable for indoor drilling projects or areas with limited clearance.

Conclusion

Choosing the right core drilling rig for your project is a pivotal decision that can greatly influence the outcome. By understanding your project’s specific requirements and considering the advantages of portable and lightweight options, you can make an informed choice. Portable and lightweight core drilling rigs offer unmatched mobility, versatility, and cost-effectiveness, making them a compelling choice for a wide range of drilling applications. Ultimately, your selection should align with your project’s goals, budget, and environmental considerations, ensuring a successful and efficient drilling operation.

songtemachine

songtemachine